Capabilities

Our Team combined has over 100 years of experience in the machining Industry. If you have a part that does not fit on a standard machine, we can build a machine to run your part.

Capable Industries

- Aerospace

- Agricultural

- Architectural

- Automotive

- Electronic

- Marine

- Medical

- Mining

- Military

- Oil & Gas

- Windows

- Automotive

- Plumbing

- Appliances

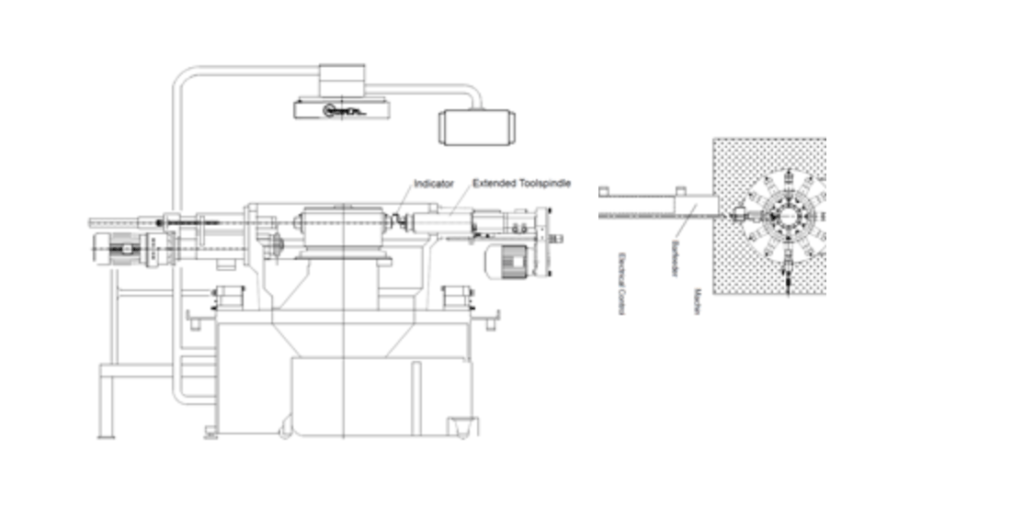

Hydromat Rotary Transfer Machining

Hydromat Pro 20 – Parts Max size 1.000”

Number of machines at s&E: 2

The HW 25-12 rotary transfer machine is a modular system consisting of up to 12 horizontal and 6 vertical spindles until rigidly mounted around a precision cast iron ring. This arrangement has the capability of providing tremendous versatility and flexibility in a turn-key machining system.

With 1″ capacity, the HW 25-12 machine is ideally suited to produce parts from bar stock or blanks up to 4″ in length.

Consistent, high productivity and precise machining, combined with the elimination of costly secondary operations make the HW 25-12 machine and outstanding solution for cost effective manufacturing.

Features

- Up to 12 horizontal & 6 machining stations

- Eliminates secondary operations

- Extreme accuracy and reliability of a Hirth ring

- Several different unit sizes available

- Coolant chiller optional

- Multiple loading and chip system options

Hydromat HW25-12 – Parts Max Size 1.000”

Number of machines at s&E: 3

The HW 25-12 rotary transfer machine is a modular system consisting of up to 12 horizontal and 6 vertical spindles until rigidly mounted around a precision cast iron ring. This arrangement has the capability of providing tremendous versatility and flexibility in a turn-key machining system.

With 1″ capacity, the HW 25-12 machine is ideally suited to produce parts from bar stock or blanks up to 4″ in length.

Consistent, high productivity and precise machining, combined with the elimination of costly secondary operations make the HW 25-12 machine and outstanding solution for cost effective manufacturing.

Features

- Up to 12 horizontal & 6 machining stations

- Eliminates secondary operations

- Extreme accuracy and reliability of a Hirth ring

- Several different unit sizes available

- Coolant chiller optional

- Multiple loading and chip system options

Hydromat HW32-16 – Part Max Size 1.750”

Number of machines at s&E: 1

With 1-3/4″ capacity, the HB 32/45-16 machine is ideally suited to produce parts from bar stock or blanks up to 6″ in length.

Consistent high production & precise machining, combined with the elimination of costly secondary operations make the HB 32/45-16 machine an outstanding solution for cost-effective manufacturing.

Features

- Up to 16 horizontal & 8 vertical machining stations

- Eliminates secondary operations

- Extreme accuracy and reliability of a Hirth ring

- Several different unit sizes available

- Coolant chiller optional

- Multiple loading and chip system options

CNC Machines

Takamaz XC-100 – 1.615” OD max, automatically loaded Lathe

Number of machines at s&E: 1

Stable cutting accuracy is realized through X axis pretension structure, increased slide rigidity and expansion of narrow ratio. In addition, the symmetrical design of the interior of the machine bed and thermal balance design from thermal displacement analysis are implemented.

Manual handle trace, automatic data backup, work counter function and others, maintenance functions are standard features that improved the usability of this machine. Furthermore, machine redesign is done so that the chuck valves and other devices are placed in front for easy access during routine maintenance.

As compared to [X-100], this machine is designed with the reduction of spindle speed acceleration and deceleration time (acceleration time: 24% reduction, deceleration time: 12% reduction), increase of spindle motor output and usage of lighter parts and LED. Thus, this machine achieves resource preservation and small power consumption.

Equipped with the new ″Σ loader″. By reviewing the performance of the basic functions, in addition to thorough weight reduction, increased shutter speed, reduction of waiting time during part loading and unloading, reduced cycle time is achieved.

Robot load 5 axis CNC Mill - HAAS UMC 750SS And Yaskawa MH12 Robot – Part Size Under 8 lbs

Number of machines at s&E: 1

Custom Machines

Heat Treatment

- Annealing

- Tempering

- Normalizing

- Hardening

- Quenching

- Stress Relieving

- Induction Process

Coatings

- Anodizing Coatings

- Zinc Manganese Phosphate

- Barrel / Rack Coatings

- Anodizing Coatings

- Solvent-Based Coatings

- Water-Based Coatings

- Rust Preventative Coatings